Addressing Corrosion in Marine Environments

Saltwater corrosion is particularly destructive due to its ability to penetrate seams, welds, and crevices where moisture becomes trapped. Traditional coating methods often fail in these areas, leading to crevice corrosion, under-film degradation, and premature component failure. In marine vessels, these failures result in increased maintenance costs, reduced operational readiness, and extended downtime.

ACL approached this challenge by developing coating systems that do more than cover exposed surfaces—they encapsulate entire components, eliminating vulnerable entry points for corrosion.

The Tidal Coat Fusion-Bonded Multilayer System

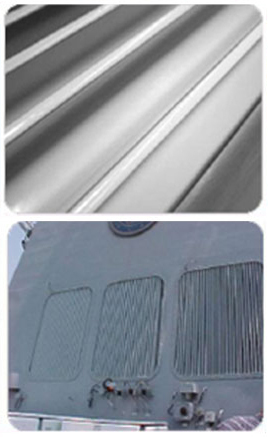

The foundation of ACL’s maritime services is the patented Tidal Coat fusion-bonded multilayer coating system. This process utilizes controlled immersion techniques that allow coating materials to fully envelop components, including internal cavities and complex geometries that are inaccessible using conventional spray methods.

By creating a continuous, uniform barrier, the Tidal Coat system effectively eliminates crevice corrosion and dramatically extends component service life. In many applications, components treated with Tidal Coat have demonstrated lifespans several times longer than those protected by traditional coatings.

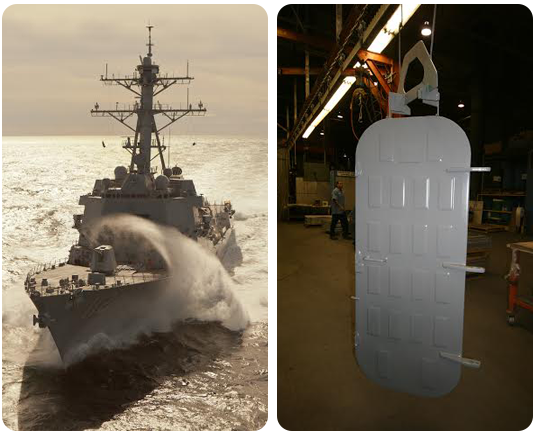

Proven Performance in Naval Applications

ACL’s Tidal Coat system has been deployed extensively within naval fleets, particularly with the United States Navy and Canadian Navy. Over more than a decade of service, the system has proven its durability in real-world maritime conditions.

Air intake and uptake louvers, which are historically prone to severe corrosion, have shown dramatic improvements when treated with Tidal Coat. In documented applications, the lifespan of these components has been extended by up to four times compared to conventional coatings. This performance improvement has translated into substantial maintenance cost savings and improved fleet availability.